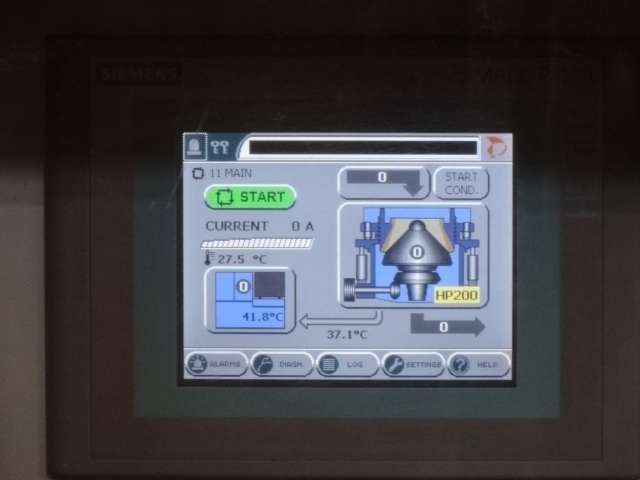

Upgrade of Crushing System – New HP 200 Metso Crusher

January 2014

Plant operations were stopped early January and during this time Mr Kumaravel and his maintenance team did a commendable job by removing an old Symons Crusher and replacing it with a new Metso unit.

The work was all completed within two weeks with a further 3 days for commissioning, testing and training and Metso France staff were very complimentary to the quality and standard of work performed by Mr Kumaravel, Plant Maint Manager and his team.

This is a new generation machine and unique combination of crusher speed, throw and cavity design. HP series cones are ideal for Secondary, tertiary and fine crushing stages. This is totally controlled by software IC7000 basic. This software (automation system) is user friendly and protects the user & machine, makes it easier to use the crusher, provides maintenance and troubleshooting data, provides the user with all the necessary information and boost productivity and prolongs the crusher’s service life.

It has lubrication and hydraulic systems mounted separately below the crusher. The lubrication system is able to lubricate all the bushes and gears of the crusher and maintain the temperature by air cooler. The hydraulic system is used for maintaining the clamping & release pressure during the operation and opening and closing of the bowl during the maintenance and gap setting.

We have installed this crusher as secondary crusher in our plant. Feed size is around -150mm and gap setting is 22-25 mm. Capacity is 150tph. Before this we were using a 3ft Symons cone crusher.

Main benefits of this crusher are high capacity and yield, easy and cost effective maintenance, easy to operate, and application flexibility.