High-Quality Demands

The main use of fluorspar was to produce hydrofluoric acid, which is used in various applications such as in refrigerants, herbicides, pharmaceuticals, high-octane gasoline, aluminium, plastics, electrical components, fluorescent light bulbs, ceramic production and optical lens production. To ensure the quality of the produced fluorspar for these applications, Kenya Fluorspar followed strict quality control protocols and testing throughout the various processes of production.

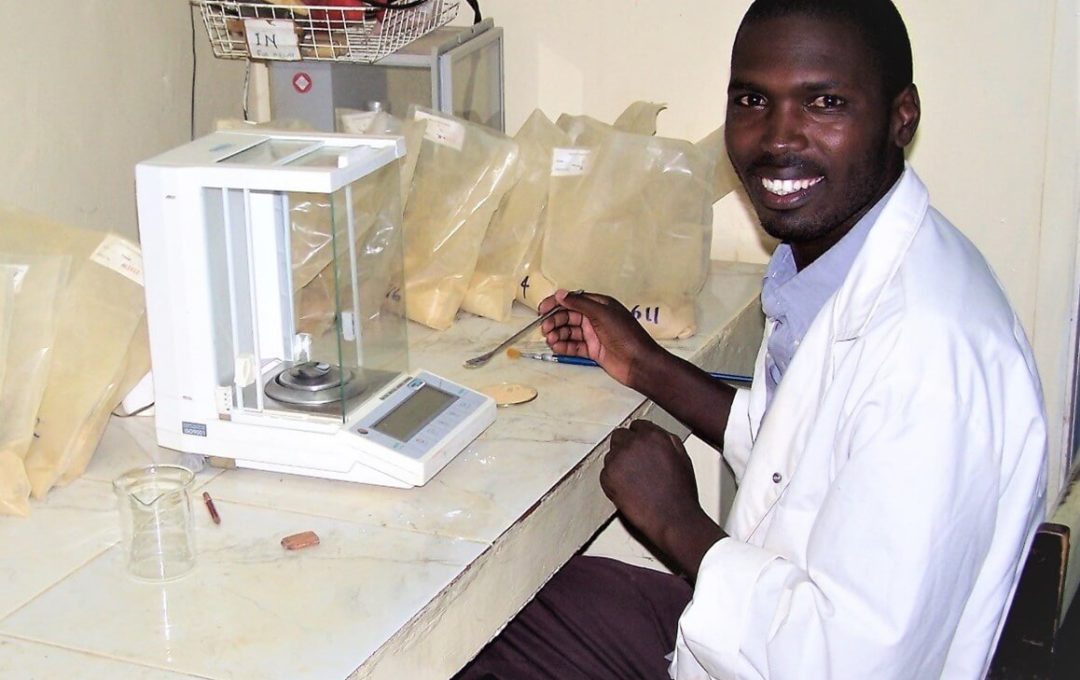

Strict quality control of the run-of-mine ore fed into the Processing Plant and final product analysis was always maintained.